Analysis and testing of technology solutions

SYNERG-E aims to implement an innovative solution to leverage synergies between energy and mobility sector. As main part of the project, 10 local battery energy storage systems (BESS) are deployed at high power charging (HPC) locations.

After an in-depth market screening of stationary BESS, it was decided to use lithium-ion batteries in the SYNERG-E project. Li-Ion batteries are able to provide and absorb energy within seconds at any state-of-charge, offer high cycle durability and provide a safe and reliable operation at very competitive costs.

Different sizes of BESS of different manufacturers are used with the following key parameters:

- The power of the BESS is in the range of 280 – 500 kW to be able to (nearly) provide 100% of the HPC power demand with the BESS for peak-shaving operation

- Li-Ion batteries with a C-coefficient of 1 (i.e. battery power / capacity) to be able to participate at grid service markets while having enough energy for charging of several electric vehicles

- Since space is often very limited at charging locations, the BESS’ casing is made in a compact way in form of a containerized solution (e.g. 20’ container or smaller)

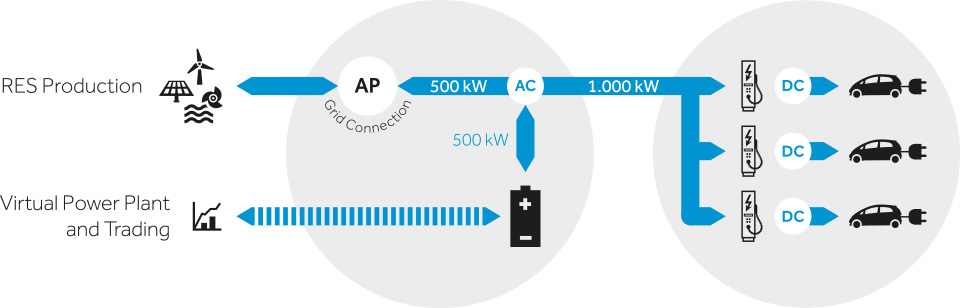

At a SYNERG-E location, several components and systems are installed in addition to the charge point infrastructure of the charge point operator (CPO) and the transformer/grid connection and official meter of the distribution system operator (DSO), namely:

- Several locally installed power meters to determine the power flow at a SYNERG-E location in real-time

- A stationary Battery Energy Storage System (BESS)

- The Micro-Grid Management System (MGMS), which is connected to all local components/systems and to a centrally located Virtual Power Plant (VPP) and a central monitoring and management system

The developed Micro-Grid Management System (MGMS) aims to serve the charge point infrastructure, the Virtual Power Plant (VPP), and the BESS in a cost-effective and sustainable way. It achieves this through a fast control loop that steers the BESS power depending on the real-time energy flows at the SYNERG-E location and communicates. Additionally, the MGMS is connected to a VPP, which links the BESS to grid services and other energy markets.

In order to not adversely affect the commercial operation of the HPC stations at the final SYNERG-E locations, it was decided to test all needed hardware and software devices (e.g. meter, BESS, MGMS, etc.) before the actual enrolment at a VERBUND-internal testing environment. This testing environment was setup at the existing VERBUND power plant site in Mellach, a municipality south of Graz in Styria, where two thermal plants are currently operated by VERBUND.

A Site Acceptance Test (SAT) procedure was developed to test the ‘basic’ functionalities and safety criteria of the BESS. The SAT includes a visual inspection, parameter verification, communication test, a verification of start-up and shut down procedures and various different test scenarios.